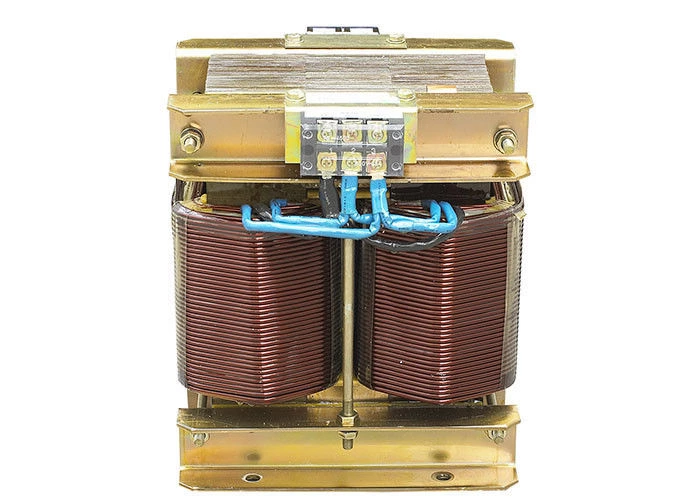

Silicon Steel Sheets For Ac Reactors

The silicon steel sheet in AC Reactors is a key material. The following is a detailed analysis of the silicon steel sheet of the AC reactor:

1. The role of silicon steel sheets in AC reactors

Magnetic conductivity: Silicon steel sheets have excellent magnetic conductivity because they contain a certain proportion of silicon elements (usually the silicon content is controlled in the range of 0.8% to 4.8%). In the energized coil, the silicon steel sheet can generate a strong magnetic induction intensity, which is crucial to the performance of the reactor.

Reducing iron loss: The power loss of the reactor working under AC state not only exists in the coil resistance, but also inevitably occurs in the iron core under the magnetization of the alternating current. This loss is called "iron loss". The hysteresis loop of silicon steel is relatively narrow, so using silicon steel as the iron core of the reactor can effectively reduce the hysteresis loss, thereby significantly reducing the heating of the iron core.

2. Types of silicon steel sheets

Oriented silicon steel sheets: After a specific heat treatment process, the grains of the steel sheet are oriented in one direction, so that it has higher magnetic permeability and lower magnetic loss in the orientation direction. This characteristic makes oriented silicon steel sheets show excellent performance in AC reactors, especially in high-frequency applications.

Non-oriented silicon steel sheets: Without special orientation treatment, its grains are randomly distributed. Although non-oriented silicon steel sheets have relatively low performance in magnetic permeability and magnetic loss, they are also widely used in various reactors due to their good isotropic properties.

3. Application advantages of silicon steel sheets

Small volume: The high magnetic conductivity of silicon steel sheets allows the reactor to be designed with a smaller volume, improving the compactness and efficiency of the equipment.

Low temperature rise: Since silicon steel sheets can effectively reduce iron loss, the temperature rise of the reactor during operation will also be reduced accordingly, which helps to extend the service life of the equipment.

No noise: High-quality silicon steel sheets also have the characteristics of small magnetostriction and reduced noise, which can improve the use experience of the reactor.

In summary, silicon steel sheets play a vital role in AC reactors. Their excellent magnetic conductivity, ability to reduce iron loss and application advantages enable reactors to have higher performance and longer service life.

Русский

Русский

Français

Français

Português

Português

Español

Español

اللغة العربية

اللغة العربية