The Difference Between Dry-type Transformer And Oil-immersed Transformer

There are significant differences between Dry Type Transformer and oil-immersed transformers in terms of structure, working principle, performance characteristics and application scenarios.

First, structurally:

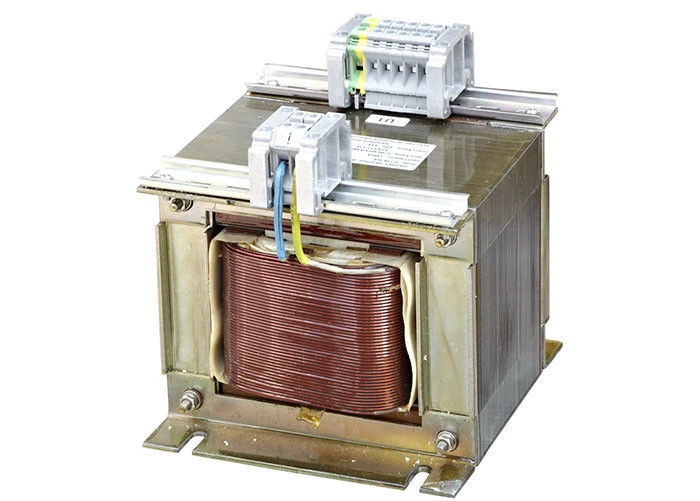

Dry-type transformers are mainly composed of cores, windings, insulating materials and shells. The windings are usually cast with epoxy resin or other polymer materials to form a solid solid insulator. Dry-type transformers have a relatively simple structure and small size.

Oil-immersed transformers are mainly composed of iron core, windings, oil tanks, insulating oil and cooling devices. The iron core and windings are immersed in transformer oil, which is used as an insulation and cooling medium. The oil tank usually adopts a sealed structure.

Secondly, in terms of working principle:

Both dry-type transformers and oil-immersed transformers realize voltage conversion through the principle of electromagnetic induction. When the primary winding is supplied with alternating current, the generated magnetic flux passes through the iron core and induces a corresponding electromotive force in the secondary winding. However, when dry-type transformers transmit electrical energy, their insulation materials play a key role.

Oil-immersed transformers have better performance in terms of heat dissipation and insulation due to the presence of transformer oil. Transformer oil can absorb and conduct heat generated by windings, and has high dielectric strength.

In terms of performance characteristics:

Dry-type transformers have the advantages of being non-flammable, free of oil leakage, easy to maintain, environmentally friendly, safe and fireproof. However, its heat dissipation performance is relatively poor, it is easy to overheat, its manufacturing cost is high, and its operation noise is loud.

Oil-immersed transformers have excellent insulation and heat dissipation properties and are suitable for high-power transformers. At the same time, it has strong short-circuit resistance and long service life. However, oil-immersed transformers have potential risks such as oil leakage and environmental pollution, and their maintenance costs are high.

Finally, in terms of application scenarios:

Due to its compact structure, easy maintenance, environmental protection, safety and other characteristics, dry-type transformers are widely used in various environments such as indoor and outdoor, especially in urban power grids, industry, transportation, construction and other fields.

Oil-immersed transformers are usually used in high-voltage and large-capacity occasions such as large substations and power systems due to their strong heat dissipation performance and high insulation strength. At the same time, oil-immersed transformers are also suitable for outdoor or harsh environments.

In summary, dry-type transformers and oil-immersed transformers each have their own advantages, disadvantages and applicable scenarios. Which type of transformer to choose should be determined based on specific application needs and conditions.

Русский

Русский

Français

Français

Português

Português

Español

Español

اللغة العربية

اللغة العربية