Why Do Million-dollar Printing Machines Use Inverters?

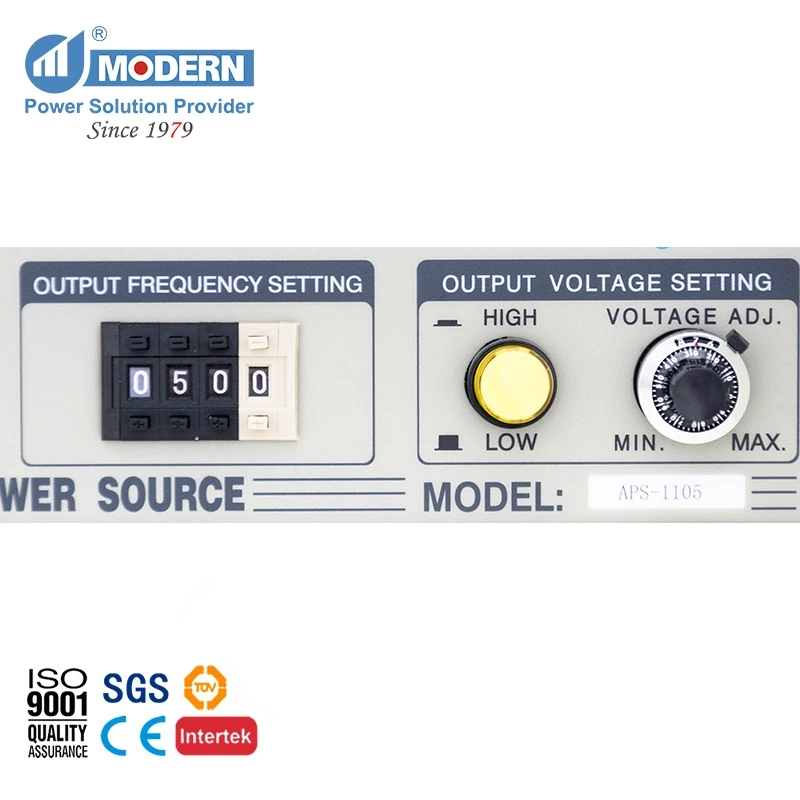

At present, when we buy printing machines, I believe many people will know that Frequency Converter has been added to the front end of the printing machine, but the previous ones were some ordinary frequency converters. Why do printing machines choose this frequency converter now?

In fact, for some equipment components, applications and systems, voltage fluctuations are very dangerous and must be controlled well. For example, high-precision printing equipment, offset printing machines, flexographic printing machines, etc., need a stable voltage environment during operation. The more sensitive components need more power protection.

The control part can work normally within the range of 3% voltage fluctuations, but the fluctuation exceeds the normal range value, which will directly or indirectly cause losses, the equipment cannot operate normally, and even burn the circuit board, shortening the service life of the equipment.

The response speed of the frequency converter is a key point to protect the back-end equipment. The response time of the traditional mechanical carbon brush type frequency converter is about 7 seconds, and the output voltage cannot be adjusted quickly and rapidly, so these confidential control circuit boards are often burned.

However, the inverter is a perfect combination of power electronics technology. It adopts innovative compensation technology, industrial-grade thyristor module configuration, precise compensation, precise sampling, and an accuracy of up to 1%. It responds quickly and has an efficiency of more than 99%. Therefore, compared with those general inverters, no inverter is the best information for these precision printers.

Of course, there are many advantages of inverters in the process of use. You can try it yourself to know what benefits the inverter can bring to us.

Русский

Русский

Français

Français

Português

Português

Español

Español

اللغة العربية

اللغة العربية